Table of Contents

What Is a Reed Switch?

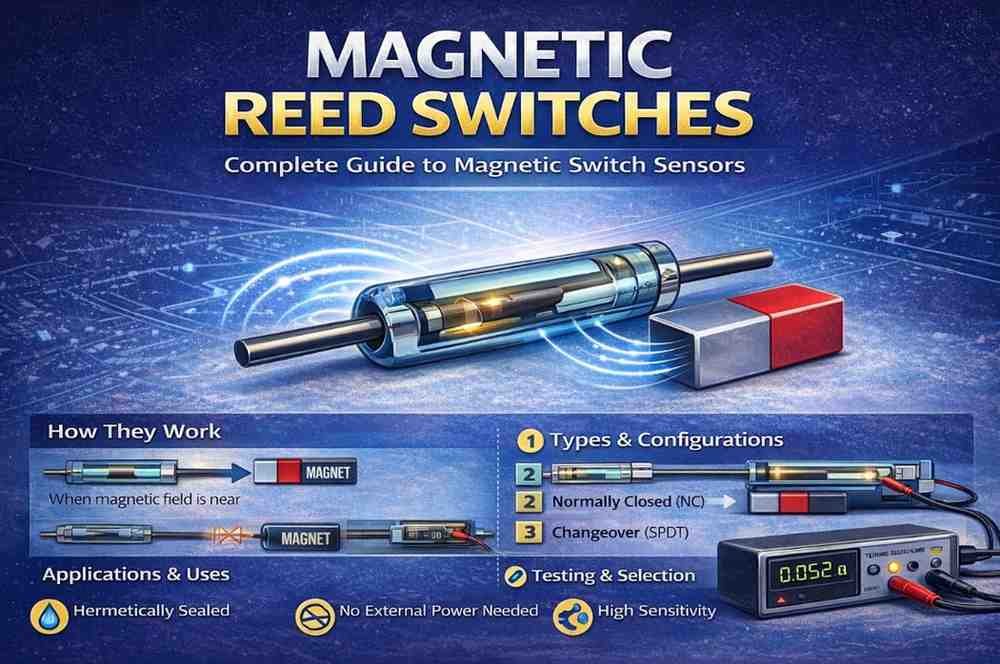

A reed switch is a type of electronic magnetic switch that operates through the presence or absence of a magnetic field. It contains two ferromagnetic metal contacts, called reeds, which are hermetically sealed inside a glass tube. When a magnetic field is applied, the reeds move toward each other and close the electrical circuit. When the magnetic field is removed, the reeds separate and the circuit opens.

Because the switching mechanism is fully sealed and contactless, reed switches provide uncommon reliability, long operating life, and uniform performance. For this reason, reed switches are hugely used as magnetic reed switch sensors in security systems, automation equipment, metering devices, and industrial control systems.

What Is a Reed Relay? In Magnetic Reed Switches

A reed relay is an electrically operated switching device that uses a reed switch as its leading switching element. The benefit of magnetic reed switches with the control capability of an electromagnetic coil. When current flows through the coil, it generates a magnetic field that activates the reed switch, causing the contacts to open or close depending on the configuration.

Unlike a basic magnetic switch that is activated by a permanent magnet, a reed relay is activated electrically. This allows the reed switch to be controlled remotely through a low-power electrical signal, making reed relays an ideal for applications that require electrical isolation, an accurate switching, and fast response.

How Does a Reed Relay Work? In Magnetic Reed Switches

A reed relay contains two main components: a hermetically sealed reed switch and an electromagnetic coil wound around it. The reed switch itself functions as a magnetic switch, while the coil generates the magnetic field needed for operation.

When electrical current passes through the coil, it creates a magnetic field around the reed switch. This magnetic field magnetizes the internal reeds of the switch, pulling them together and closing the circuit. When the current is removed, the magnetic field collapses, the reeds demagnetize, and the contacts return to their original position. This working principle allows the reed relay to provide clean, bounce-free switching with very low power consumption.

Key Features of Reed Relays

One of the leading advantages of a reed relay is its better electrical isolation between the control circuit and the load circuit. Since the reed switch is sealed inside glass, it is protected from dust, moisture, and corrosion, resulting in high reliability and long operational life.

Reed relays also provide fast switching speeds, low contact resistance, and uniform performance over millions of cycles. Because the switching element is a magnetic reed switch sensor, the relay can handle very small signals without signal warp, which is difficult for normal mechanical relays.

How Does a Reed Switch Work?

The operation of a reed switch is based on magnetic principles and mechanical movement, without the need for any external power source.

When a magnet approaches the reed switch, the magnetic field magnetizes the internal reeds. This magnetization causes the reeds to attract each other and touch, completing the circuit. Once the magnet moves away, the magnetic field collapses, the reeds lose magnetization, and the contacts return to their original open position.

This simple working principle reduces friction, sparking, and wear, allowing reed switches to perform millions of operations reliably. Because no power is required to maintain the switching state, reed switches are ideal for low-power and battery-operated systems.

Types of Reed Switches Based on Contact Configuration

Normally Open (NO) Reed Switch

A normally open reed switch remains open when no magnetic field is present. When a magnet is applied, the contacts close and current flows through the circuit. This is the most usually used reed switch configuration and is largely found in door and window sensors, safety interlocks, and position detection systems. Many applications simply refer to this configuration as a no magnetic switch because the circuit is inactive in the absence of a magnet.

Normally Closed (NC) Reed Switch

A normally closed reed switch, also referred to as a reed normally closed switch, remains closed when no magnetic field is present. When a magnet approaches, the contacts open and break the circuit. This design is usually used in fail-safe systems, where a broken wire or disconnected sensor must trigger an alarm or fault condition.

Changeover (SPDT) Reed Switch

Changeover or SPDT reed switches include one common terminal and two output terminals. Depending on the magnetic field, the common terminal switches between the normally open and normally closed contacts. These switches are used in industrial logic circuits, control panels, and applications requiring signal switching between two states.

Key Technical Parameters of Reed Switches

Magnetic Sensitivity (AT Value)

Magnetic sensitivity is defined by the Ampere Turns (AT) value of the reed switch. The AT value shows how strong a magnetic field must be to activate the switch. Lower AT values correspond to higher sensitivity and longer sensing distance, while higher AT values require stronger magnetic fields. Selecting the wrong AT value is one of the most common reasons magnetic reed switch sensors fail in real-world applications.

Sensing Distance and Magnet Selection

Sensing distance is not a fixed specification. It depends on the strength of the magnet, the direction of the magnet relative to the reed switch, the AT value of the switch, and installation alignment. A strong magnet with incorrect orientation may perform worse than a weaker magnet placed correctly. This is why testing the reed switch and magnet together in the real application is always recommended.

Electrical Ratings

Every reed switch has defined electrical limits, including maximum switching voltage, current, and power. Increasing these ratings can cause contact welding, increased resistance, or complete switch failure. Special attention is required when switching inductive loads such as relays, solenoids, or motors. Without proper protection, voltage spikes generated by inductive loads can majorly reduce the electrical life of the switch.

Contact Material and Plating

The contact material of a reed switch directly affects its electrical life and performance. Different contact platings are designed for low-signal switching, higher current switching, or extended durability. Using the wrong contact material can result in unreliable signals, especially in accuracy applications where very low currents are involved.

Types of Magnetic Switches Based on Mounting Style

Surface Mount Magnetic Switch

A surface mount reed switch is designed to be mounted directly on the surface of doors, panels, or enclosures. These switches are easy to install and regularly used in security systems and access control applications. A surface mount reed switch is often preferred where drilling or embedding is not possible.

Recessed Mount Magnetic Switch

A recessed magnetic switch is installed inside a drilled hole in doors or frames, making it nearly invisible once installed. This type of switch is hugely used in leading security installations where aesthetics and tamper resistance are important. Recessed magnetic switches provide better mechanical protection and alignment stability compared to surface-mounted designs.

Overhead Mount Magnetic Switch

An overhead magnetic switch is installed above doors, shutters, or industrial gates. These switches are regularly used in warehouses, rolling shutters, and heavy-duty industrial applications where side mounting is not practical. An overhead magnetic switch is designed to withstand vibration, misalignment, and hard environmental conditions.

Common Applications of Reed Switches

Security and Alarm Systems

Reed switches are a core component in intrusion detection systems, door and window sensors, and tamper detection devices. Their sealed construction make sure reliable operation over long periods without maintenance.

Industrial Automation

In industrial automation, reed switches are used for position sensing, limit detection, and machine status monitoring. Their resistance to dust, moisture, and vibration makes them an ideal for factory environments.

Energy Meters and Utility Equipment

Utility meters depend on magnetic reed switch sensors for pulse counting, flow measurement, and anti-tamper mechanisms. Accuracy and long-term stability are critical in these applications.

Automotive and EV Applications

Reed switches are used in automotive and EV systems for position confirmation, safety interlocks, and flap detection, where dependable operation is important.

Consumer Electronics and Home Appliances

Magnetic reed switches are hugely used in consumer electronics and household appliances to detect door position, make sure user safety, and improve energy efficiency. Their compact size, silent operation, and long electrical life make them an ideal sensing solution for appliances that are opened and closed repeatedly during daily use.

In refrigerators, magnetic reed switch sensors are used to detect whether the door is open or closed. A small magnet is embedded in the door, while the reed switch is installed inside the cabinet frame. When the door is closed, the magnetic field activates the reed switch, confirming a closed condition. If the door is left open, the magnetic field is removed, and the switch changes state. As a result, the refrigerator can trigger a warning alarm, turn on an internal light, or adjust compressor operation /to prevent unnecessary energy loss. This improves both energy efficiency and food preservation.

In washing machines, magnetic reed switches are regularly used as lid or door safety interlocks. The reed switch make sure that the washing cycle starts only when the door is properly closed. If the door opens during operation, the magnetic field is removed, causing the switch to change state and immediately stop the motor or drum rotation. This prevents water leakage, mechanical damage, and potential user injury, making the appliance safer and more reliable.

In microwave ovens, magnetic switches play an important safety role by detecting the door position. A reed normally closed or normally open configuration is selected based on the safety logic of the appliance. When the door is closed, the magnetic field confirms a safe condition, allowing the microwave to operate. If the door is opened, the magnetic field is removed and the circuit opens, immediately damage microwave radiation. This makes sure that the appliance cannot operate in an unsafe condition and protects the user from exposure.

In electric ovens, magnetic reed switches are used to detect oven door status during operation. When the door is opened, the reed switch signals the control system to switch off heating elements or adjust temperature control. The result is improved user safety, reduced heat loss, and better temperature regulation. In advanced ovens, the switch also helps manage interior lighting and cooling fan operation.

In clothes dryers, magnetic reed switches are used to monitor door closure before and during operation. The dryer motor and heating elements are allowed to operate only when the door is securely closed. If the door opens mid-cycle, the magnetic reed switch sensor immediately signals the control circuit to stop operation. This prevents overheating, mechanical hazards, and fire risks, make sure safe and controlled drying.

In dishwashers, magnetic reed switches are installed to confirm that the door is fully closed and sealed before water intake and pump operation begin. If the door is opened during a wash cycle, the reed switch detects the absence of the magnetic field and stops water flow and motor operation. This prevents water leakage, protects internal components, and increases an overall appliance safety and reliability.

Overall all these consumer electronics applications, magnetic reed switch sensors provide exact position detection without requiring external power. The result is a simple, cost-effective, and highly reliable sensing solution that improves safety, energy efficiency, and product durability. This is why appliance manufacturers continue to prefer reed switches over more complex electronic sensors for critical safety and position-detection functions.

Reed Switch vs Hall Effect Sensor

Reed switches and Hall sensors are often compared for magnetic sensing applications. Reed switches do not require a power supply, provide excellent electrical isolation, and are cost-effective. Hall sensors require continuous power and electronic circuitry but provide faster switching and analog outputs. For low-power, cost-sensitive, and safety-critical applications, reed switches remain the preferred solution.

Common Reasons for Reed Switch Failure

Most failures occur due to incorrect application rather than manufacturing defects. Common issues include incorrect magnet selection, improper alignment, exceeding electrical ratings, lack of inductive load protection, and ignoring environmental conditions. Understanding these factors during design greatly improves field reliability.

How to Select the Right Reed Switch

Selecting the right reed switch begins with defining the application requirements. The sensing distance, magnet type, AT value, electrical load, and environmental conditions must all be considered. Following a structured selection process makes sure reliable performance and long service life.

Importance of Manufacturing Quality

The reliability of a reed switch depends heavily on manufacturing quality. Hermetic sealing, accurate contact alignment, consistent AT calibration, and life-cycle testing are important. Low-quality products may meet initial specifications but often fail under real operating conditions.

Reed Switch Sensor Manufacturer and Bulk Supply

As a Sensor Manufacturer and Bulk Supplier, 1 LEAP Technologies designs and manufactures reed switches specifically for Indian industrial and commercial applications. Custom AT values, lead configurations, and mounting styles are available to meet specific customer requirements. The focus is not only on datasheet compliance but also on long-term reliability in real-world environments.

The mounting position should be adjusted so that the actuating magnet stops at the center of the reed switch’s operating range. Center positioning provides stable actuation, reduces sensitivity to minor alignment changes, and make sure regular performance over time. By following these mounting and installation guidelines, users can majorly improve the reliability, accuracy, and service life of reed switches over a huge range of applications.

Testing and Troubleshooting Reed Switches

Proper testing and systematic troubleshooting are important to make sure that a reed switch operates reliably throughout its service life. The following guidelines help identify potential issues and maintain reliable performance in real-world applications.

Dynamic Contact Resistance (DCR) Testing

Dynamic Contact Resistance testing is one of the most accurate methods for evaluating the condition of a reed switch. It measures the true contact resistance between the reed blades during operation, rather than at a static state. DCR testing helps detect early signs of problems such as overstressed switches, cracked glass seals, internal contamination, or degraded contact surfaces that may not be visible through basic inspection.

Avoid Using Standard Multimeters

Conventional multimeters are not recommended for testing reed switches, especially in low-level signal applications. Multimeters typically operate at very low power levels, which can lead to oxidation buildup on the contact surfaces over time. Instead, reed switches should be tested in a proper test circuit capable of providing at least 3 watts of power to make sure reliable contact cleaning and accurate results.

Temperature Effects on Performance

Temperature has a direct impact on reed switch behavior. As temperature increases, the electrical resistance of the reed switch generally rises, while the magnetic force acting on the reeds decreases. These opposing effects can influence switching reliability, particularly in high-temperature environments. Temperature variations should always be considered during testing and troubleshooting.

Failure Mode Identification

When a reed switch does not perform as expected, identifying the exact failure mode is critical. Common failure symptoms include no output indication, constant activation, or intermittent or flickering signals. Each failure mode points toward different root causes, such as magnet misalignment, electrical overstress, or environmental interference, allowing for more effective troubleshooting.

Vernier Adjustment for Precise Positioning

In applications requiring precise alignment, Vernier switch setting knobs can be used to fine-tune the reed switch position without the need for tools. This is particularly useful in sensitive sensing applications where small positional changes significantly affect performance and repeatability.

By applying these testing and troubleshooting practices during selection, installation, and maintenance, users can significantly improve the reliability, accuracy, and operational lifespan of reed switches across a wide range of applications

Mounting and Installation Best Practices for Reed Switches

Correct mounting and installation plays an important role in making sure reliable and repeatable operation of reed switches. Following these best practices helps prevent false triggering, premature failure, and performance variabilities.

Correct Orientation

For real activation, the reed switch should be mounted parallel to the path of the moving magnet. Proper alignment make sure an uniform magnetic field is applied to the switch as the magnet approaches and moves away, resulting in regular and repeatable switching behavior.

Avoid Magnetic Interference

When multiple reed switches or magnetic activation are used in close proximity, adequate spacing must be maintained to avoid magnetic interference. As a general guideline, reed switches should be installed at least 40 mm apart when operating in parallel configurations to prevent unintended activation caused by overlapping magnetic fields

Minimize Wiring Length

The wiring between the reed switch and the load should be kept as short as possible. Longer wire lengths can increase in-rush current and electrical stress during switching, which may reduce the operational life of the switch. Proper cable routing also helps minimize electrical noise and signal distortion.

Ensure Secure Mounting

Reed switches must be securely mounted using the correct tightening torque specified by the manufacturer. Over-tightening can damage the switch body or glass capsule, while insufficient tightening may cause the switch to shift from its detection position, leading to unreliable operation

Optimize Magnet Positioning

The mounting position should be adjusted so that the actuating magnet stops at the center of the reed switch’s operating range. Center positioning provides stable actuation, reduces sensitivity to minor alignment changes, and make sure regular performance over time. By following these mounting and installation guidelines, users can majorly improve the reliability, accuracy, and service life of reed switches over a huge range of applications.

Final Conclusion

Reed switches continue to be one of the most reliable and cost-effective magnetic sensing technologies available today. With correct selection, proper installation, and quality manufacturing, reed switches provide long service life, reliable performance, and excellent value over a huge range of applications.