A New Era of Automation in the Food Industry

The food industry is undergoing a rapid transformation driven by rising energy costs, strict hygiene regulations, labour shortages, and increasing sustainability expectations. From commercial kitchens and food processing plants to cold storage facilities and QSR outlets, operational efficiency has become a critical performance metric. Smart sensors now play a central role in helping facilities meet these challenges by optimizing energy usage, improving security, enhancing hygiene, and supporting sustainability frameworks such as Smart Energy Optimization and Green Automation Solutions.

Traditional manual controls often fall short in dynamic food environments. Lights remain on unnecessarily, refrigerating zones suffer temperature fluctuations, and unauthorized access goes unnoticed. Smart sensors overcome these limitations by automatically monitoring activities, controlling equipment, and enabling real-time decision-making. As a result, food facilities can reduce operational costs, strengthen safety protocols, and achieve compliance with global standards such as HACCP, ISO 22000, and FSMA.

Role of Smart Sensors in Modern Food Facilities

Smart sensors enable continuous monitoring of environmental conditions and human activity. Instead of relying on manual processes, facilities use automated systems to ensure precise, consistent control across lighting, access, temperature, and hygiene zones. This transition not only reduces human error but also supports the larger industry move toward data-driven operations, sustainability performance, and Green Credits & Carbon Savings Advisory initiatives.

360° Ceiling Mount Occupancy Sensor (1L-PS041): Automating Lighting Efficiency

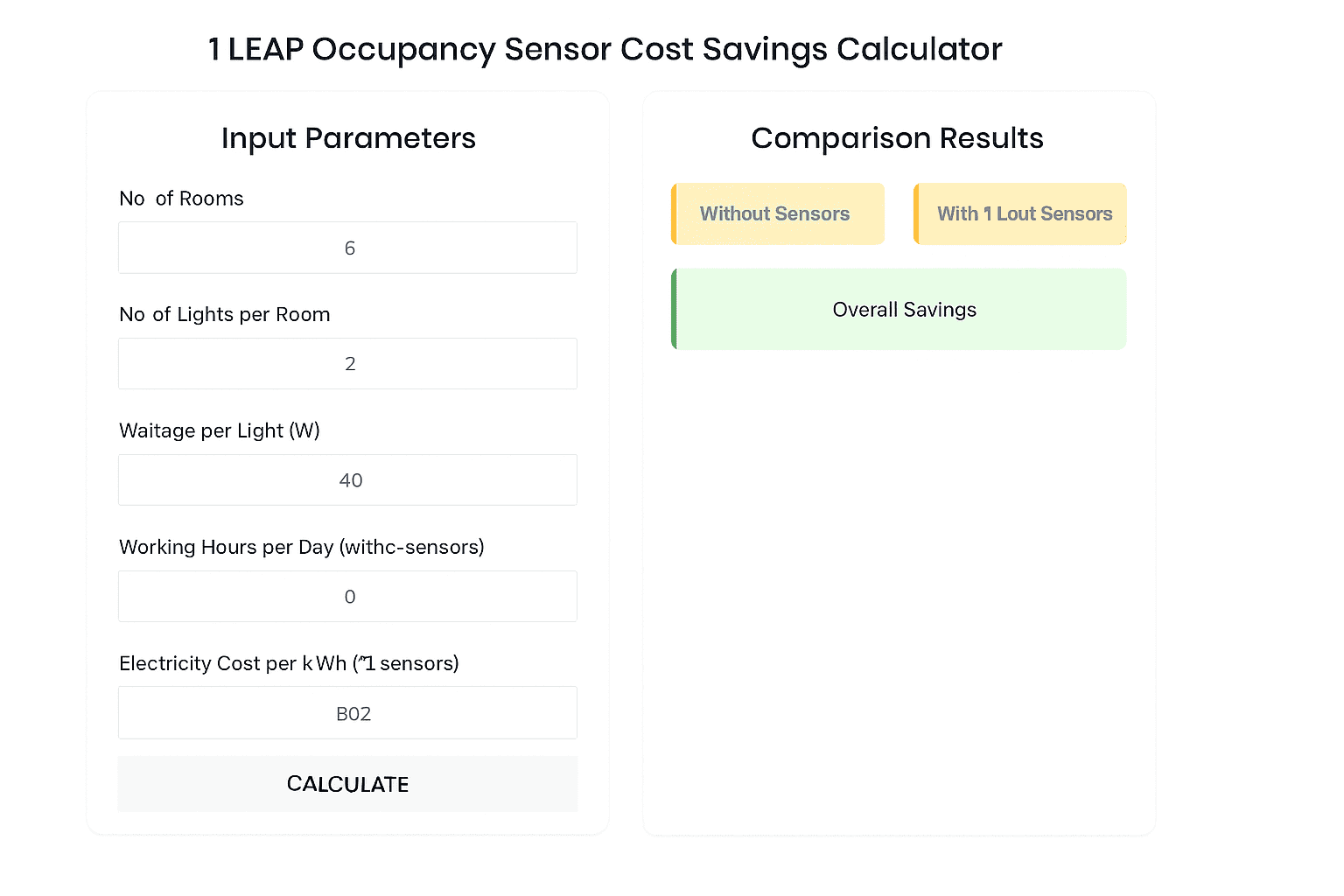

Lighting accounts for a significant portion of energy consumption in food facilities, particularly in kitchens, freezers, warehouses, packaging zones, and preparation areas. The 1L-PS041 Ceiling Mount Occupancy Sensor is designed to eliminate this unnecessary energy load. Using dual-technology motion detection—PIR and ultrasonic sensing—it identifies human presence with high accuracy and switches lighting on only when required.

In restaurant kitchens, where staff frequently move between prep counters, pantries, and cold rooms, lights are often left on even during long idle periods. The occupancy sensor solves this by activating lights instantly when motion is detected and turning them off once the area is unoccupied. This simple automation can reduce lighting energy consumption by up to 30% and extend the lifespan of fixtures. The benefit is even greater in walk-in freezers, where reduced lighting usage minimizes internal temperature rise and reduces compressor load.

The sensor also integrates seamlessly into Smart Energy Optimization systems. Its data can be synchronized with HVAC operations, used for load balancing, and incorporated into energy audits supporting green certifications. This makes it an essential component for food facilities aiming to create energy-efficient lighting strategies

Magnetic Reed Switch Sensors: Strengthening Access Control and Security

Food processing plants and storage facilities require strict control over who enters certain areas and when. Magnetic Reed Switch Sensors provide a reliable, automated way to track the opening and closing of critical access points. Although small in size, these sensors play a vital role in maintaining security, compliance, and operational discipline.

In processing environments, unauthorized access to raw ingredient zones, allergen handling areas, or chemical storage rooms can compromise safety protocols and lead to major compliance violations. Reed switches generate immediate alerts when doors are opened, helping supervisors monitor activities in real time. They also create an automated digital log of door movements, which is essential for audit trails and regulatory inspections.

Cold storage facilities benefit significantly from reed switch sensors as well. A refrigerator or freezer door left open for too long can cause temperature drift, spoil products, and strain refrigeration compressors. A reed switch instantly detects such incidents, enabling staff to respond before losses occur. Beyond internal operations, reed switches enhance perimeter security in warehouses by detecting unauthorized entry and supporting inventory accuracy.

By integrating with building management systems, reed switches contribute to broader Green Automation Solutions. They support digital SOP enforcement, maintain accountability, and ensure controlled movement throughout the facility—all essential elements of modern food industry automation.

Air Curtain Sensors: Ensuring Hygiene and Environmental Stability

Air curtains are widely used in food environments to prevent dust, insects, fumes, and external air from entering clean zones. However, running them continuously results in unnecessary energy consumption. Air Curtain Sensors solve this problem by activating the air curtain only when the door opens and shutting it off once the door is closed.

In industrial bakeries and hot kitchens, where internal climate control is crucial for consistent product quality, air curtain sensors ensure that environmental stability is maintained during staff movement. By preventing external air intrusion, they help maintain consistent temperature and humidity levels—key factors in dough proofing and baking efficiency.

Cold chain facilities also benefit from the precise control provided by air curtain sensors. They help maintain internal chill, reduce frost buildup, and minimize heat exchange at entry points. Similarly, restaurants, butcheries, and food retail outlets rely on these sensors to protect hygiene barriers at entrances, prevent insect entry, and maintain customer comfort.

The energy savings from air curtain sensors can range between 15% and 20%, making them a valuable tool for reducing HVAC load and supporting Smart Energy Optimization strategies throughout the facility.

Building an Integrated Smart Facility: Sensors as the Backbone

The true power of smart sensors emerges when they function as part of a unified automation ecosystem. Occupancy sensors, door sensors, air curtain sensors, environmental sensors, and energy meters can all be connected to a centralized monitoring platform. This enables synchronized lighting and HVAC control, better temperature regulation, automated compliance reporting, and predictive maintenance.

By integrating real-time data across systems, food facilities enhance operational visibility and reduce human dependency. This transformation supports long-term sustainability strategies and contributes to Green Credits & Carbon Savings Advisory calculations. Facilities can easily document reductions in energy usage, carbon emissions, and operational inefficiencies—offering measurable benefits to ESG reporting frameworks.

Building an Integrated Smart Facility: Sensors as the Backbone

The true power of smart sensors emerges when they function as part of a unified automation ecosystem. Occupancy sensors, door sensors, air curtain sensors, environmental sensors, and energy meters can all be connected to a centralized monitoring platform. This enables synchronized lighting and HVAC control, better temperature regulation, automated compliance reporting, and predictive maintenance.

By integrating real-time data across systems, food facilities enhance operational visibility and reduce human dependency. This transformation supports long-term sustainability strategies and contributes to Green Credits & Carbon Savings Advisory calculations. Facilities can easily document reductions in energy usage, carbon emissions, and operational inefficiencies—offering measurable benefits to ESG reporting frameworks.

Sustainability Impact: Enabling Green Automation Solutions

The global shift toward sustainability has made energy efficiency and resource conservation top priorities for the food industry. Smart sensors directly support these goals by providing data-driven control, preventing waste, and reducing environmental impact

Reducing lighting consumption, improving HVAC efficiency, and maintaining temperature stability leads to lower electricity bills and decreased carbon emissions. More importantly, the automated logs and energy datasets generated by sensors help facilities meet requirements for green certifications and claim carbon credits through advisory programs.

Smart Energy Optimization, supported by sensor-based insights, enables organizations to align with international sustainability targets and demonstrate real progress in energy reduction. This not only reduces operational costs but also positions them as responsible, future-ready industry players.

Real-World Success Stories

Across India, food businesses are already witnessing the measurable impact of sensor-driven automation. A New Delhi–based food processor experienced a 25% reduction in energy consumption in its storage and packaging facilities after implementing occupancy sensors. Similarly, a bakery chain in Mumbai achieved a 15% decrease in heating losses and improved production consistency after installing air curtain sensors across multiple outlets. These examples highlight how small, strategic automation upgrades can lead to significant long-term gains.

Conclusion: Smart Sensors Are the Future of Food Facility Operations

Smart sensors have become indispensable tools in building efficient, safe, and sustainable food industry operations. Occupancy sensors eliminate lighting waste, magnetic reed switches strengthen access control and compliance, and air curtain sensors protect hygiene and environmental stability. Together, they form the foundation of intelligent food facilities that prioritize efficiency, safety, and sustainability

As food businesses continue to evolve, smart sensors will play a central role in shaping next-generation automation, enabling deeper analytics, predictive monitoring, and continuous improvement. With their contribution to Smart Energy Optimization, Green Automation Solutions, and Green Credits & Carbon Savings Advisory frameworks, smart sensors are not merely technological upgrades—they are strategic investments in the future of food industry performance.