Green Automation & Carbon Smart Solutions

By 1 LEAP Technologies – Engineering India’s Green Future

Factories, warehouses, and commercial facilities lose a surprising amount of electricity not because their machines consume too much power, but because small daily habits often go as unseen. Lights remain switched on in empty rooms, air curtains operate even when there is no movement at the entrance, doors stay open longer than required, and certain areas continue drawing power simply due to the human oversight. These small leaks, when gather over the multiple shifts, quietly increase monthly electricity bills.

1 LEAP CarbonSmart Systems, powered by CarbonSmart Sensor Technology, focuses on solving these practical, everyday inefficiencies through sensor-based automation that makes sure an electricity is used only when it is genuinely needed. This shift towards an efficient consumption also supports businesses working to earn Green Credits and reduce in their overall environmental footprint.

Now Understanding the Real Sources of Electricity Waste

The Hidden Cost of Carelessness and Manual Errors

Most facilities do not suffer from the large technical faults; instead, they face routine operational oversights that lead to non-essential power consumption. Areas such as washrooms, storerooms, corridors, utility spaces, and visitor zones often remain clarify even when it is not in use. Air curtains continue running for long durations, regardless of foot traffic, and door openings frequently disturbs an internal cooling or air balance.

These issues may appear into minor individually, but when repeated daily over many sections of a facility, they create noticeable energy loss. 1 LEAP CarbonSmart Systems helps identify and remove such wastage by automating the simplest but most frequently ignored activities—building a more energy-efficient environment that contributes positively toward the Carbon Credits and maintainability obedience.

What 1 LEAP Does – Deep Technical Breakdown

We don’t just audit. We build a complete green transformation roadmap powered by real data. Energy Consumption Mapping

We start by analyzing your factory’s complete energy profile. Using modern tools and CarbonSmart Sensor Technology, we capture accurate insights on:

- Machine-wise electricity usage

- Peak load timing

- High-loss zones

- Standby and idle energy waste

- Inefficient lights, motors, appliances

- Temperature or airflow-based energy leakage

This reveals hidden wastage that is impossible to detect through manual inspection.

Waste & Loss Identification

Every factory loses 20–40% energy through unnoticed inefficiencies. We identify:

- Idle-running losses

- Overvoltage/undervoltage inefficiencies

- Human-negligence wastage

- Improper equipment settings

- HVAC leakage

- Light and airflow wastage zones

These insights form the core of our Energy Waste Elimination Systems—designed to reduce waste at its source.

Automation Upgrades

We implement industrial-grade, low-cost retrofit automations that require no machinery changes. These include:

- Occupancy-based automation

- Magnetic reed switch controls

- Temperature-driven automation

- Fan/light optimization

- Air curtain efficiency enhancement

- Motion-sensor timing systems

- Plug-and-play smart controllers

These upgrades typically recover their cost within 30–90 days.

Carbon Footprint & Green Credit Readiness

This is your gateway to future compliance and eligibility for Carbon Credits. We calculate:

- Total annual carbon footprint

- Reduction potential after improvements

- Green Credit Programme readiness

- Emission benchmark alignment

- Compliance capacity

- Future sustainability audit scores

This make sure that your factory stays on top in India’s fast-changing sustainability landscape.

What 1 LEAP Provides

Our approach provides far more than a basic inspection. We start by mapping how energy flows through your factory—machine by machine and zone by zone—using modern monitoring and CarbonSmart Sensor Technology to detect patterns invisible to the naked eye. This reveals where electricity is being productively used and where it is silently lost through leakage or inability. Many factories are surprised to discover machines running uselessly, appliances consuming excess wattage, and airflow or lighting patterns causing continuous wastage.

With this energy map in hand, we identify every source of operational loss. Whether it’s idle running, outdated motors, incorrect temperature settings, voltage fluctuations, or behavior-driven misuse, we quantify the cost of each inefficiency. This data allows us to design targeted improvements supported by our Energy Waste Elimination Systems, which makes sure that every upgrade operate measurable savings.

We then develop a customized automation plan according to your layout and machinery. Our Green Automation Solutions combines perfectly with your existing setup, requiring no major alterations. From occupancy-based controls to air curtain enhancement and sensor-based shutdown mechanisms, each automation upgrade is built for quick ROI, typically within 30 to 90 days.

Finally, we calculate your complete carbon footprint, estimate your emission reduction potential, and prepare your documentation for Carbon Credits. This positions your factory for upcoming regulations, ESG demands, and green incentive frameworks.

Why Manual Monitoring Isn’t a Long-Term Solution

Automation Makes Sure The Consistency Over An Every Shift

In busy workplaces, expecting staff to regularly switch lights on and off, manage air curtain operation, or maintain disciplined door use is unworkable. Human error is natural, especially in environments requires the continuous movement and multitasking. Sensor-based automation removes this dependency overly.

1 LEAP’s smart sensors detect occupancy, movement, and door activity and responds quickly by activating or deactivating the connected systems. This makes sure a consistent energy discipline all over the day, regardless of shift load or staff availability. By maintaining this automated efficiency, facilities naturally in reducing the optional energy use—an important step in line up with modern sustainability practices such as Green Credits programs.

How LEAP Sensors Bring Practical Energy Savings

Intelligent Lighting, Airflow, and The Door Management

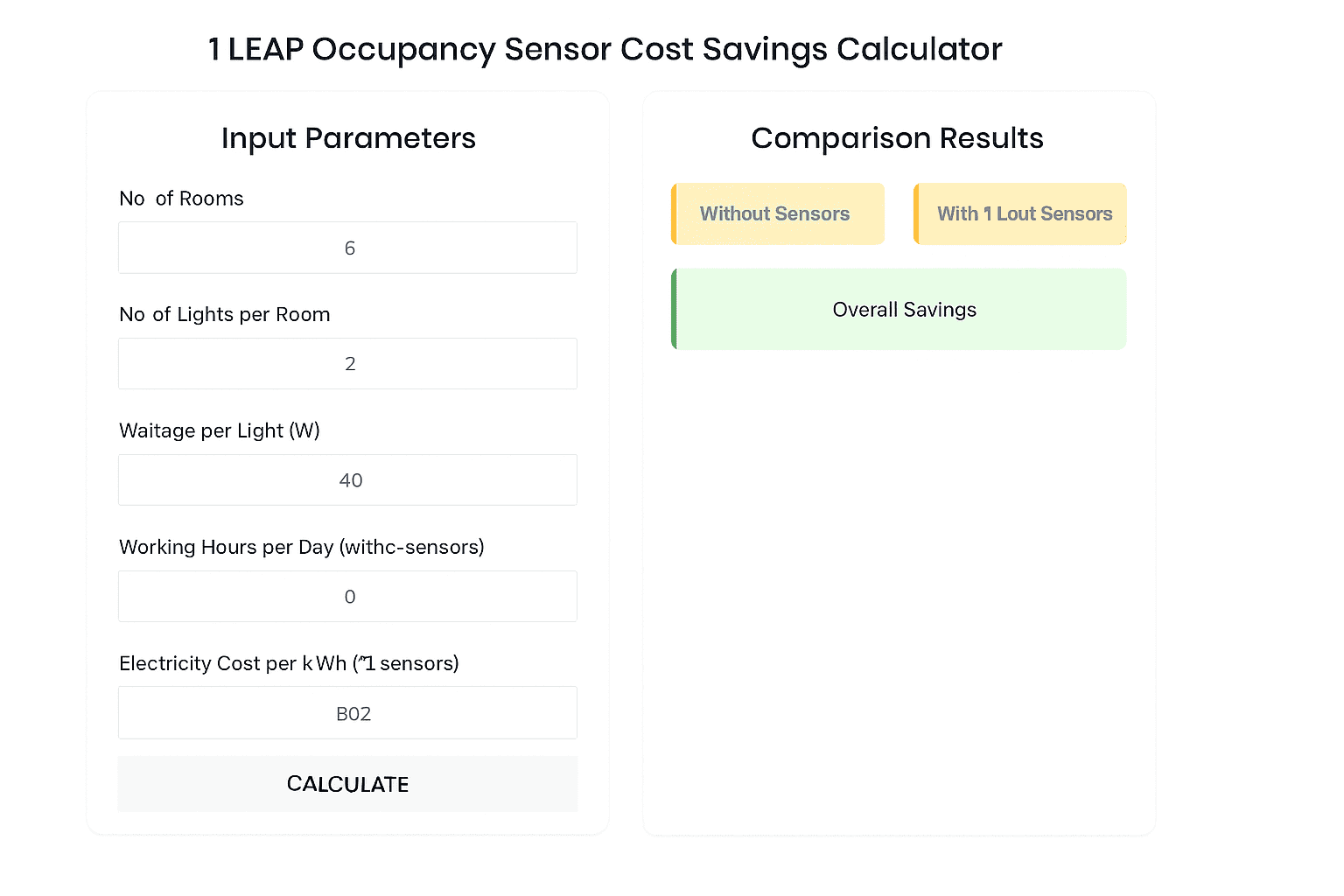

1 LEAP CarbonSmart Systems uses a combination of Occupancy Sensors, PIR Motion Sensors, Air Curtain Sensors, and Eco-Friendly Magnetic Reed Sensors to make the facilities more energy efficient without requiring any multiplex setup. Occupancy and motion sensors automatically turn lighting on when a person enters and switch it off when the area becomes empty, makes sure that electricity is never wasted on empty spaces.

Air curtain sensors activate their airflow only when the movement is detected near an entry points, preventing extra runtime and reducing motor load. Magnetic reed switches maintain controlled door operation, supporting better cooling efficiency and minimizing environmental leakage. Together, these simple automations create a reliable and measurable reduction in an electricity use while strengthening your facility’s contribution to CarbonSmart Sensor Technology–based on sustainability goals.

Designed for The Real Indian Factory Conditions

Durable, Reliable, and The Low-Maintenance

Indian industrial environments often deal with dust, fluctuating temperatures, frequent foot movement, and extended working hours. 1 LEAP sensors are construct on keeping these conditions in mind, Providing the powerful performance and low maintenance requirements. They operate smoothly in workshops, production floors, warehouses, retail entrances, textile units, furniture factories, and many other settings.

Since the automation is presence-based, the system makes sure the visible bill reduction over time without requiring staff involvement or continuous supervision. These daily savings, backed by the smart automation, also contribute to the long-term environmental benefits and indirectly support to the path towards Carbon Credits.

Easy to Install, and Easy to Integrate

Automation Without Disrupting Your Existing Setup

One of the strong advantages of 1 LEAP CarbonSmart Systems is its similarity with the existing architecture. The sensors can be installed without structural changes or downtime, making them an ideal for facilities that cannot afford the production disturbance.

Once mounted and configured, they start operating quickly and continue in optimizing lighting and airflow based on real-time occupancy. This simple but effective automation allows businesses to increase an operational efficiency, reduce wastage, and line up in their facility with energy-saving practices that cheer up the more sustainable outcomes.

A Practical Step Toward Smarter Operations

Realistic, Reliable, and Result-Driven Automation

1 LEAP CarbonSmart Systems does not promise deep industrial audits or complex machine-level energy analytics. Instead, it provides you what matters most to an everyday operations—reducing an avoidable electricity waste, improving discipline in lighting and airflow usage, and lowering dependency on manual control.

These improvements may appear simple, but they create meaningful savings over time and help businesses in operate more responsibly. In an environment where every unit of electricity counts, adopting smart automation becomes a valuable and realistic step toward smoother, more sustainable operations that support Green Credits, contribute to Carbon Credits, and reflect a forward-looking environmental approach through CarbonSmart Sensor Technology.