Unveiling the Magic of NO Type Reed Switches: A Comprehensive Guide

Reed switches have quietly powered many innovations over the decades, and today we shine a light on the unsung hero—the NO type reed switch. In this guide, you’ll discover its inner workings, applications, and why it remains a staple in our modern yet traditionally rooted technology landscape.

A Brief History of Reed Switches

The reed switch was invented in 1936 by Walter B. Ellwood at Bell Labs. Initially developed for use in telecommunications, these switches quickly gained popularity due to their reliability, simplicity, and low power consumption. By the 1950s and 60s, reed switches were widely adopted in computing, security systems, and industrial automation. Over the years, advancements in materials and manufacturing processes have further enhanced their durability and performance, securing their place in modern applications.

First Electromagnetic Switch design. Image Credit – Wikipedia

{Reed switch diagrams from Walter B. Ellwood’s 1941 patent,[4] Electromagnetic switch. It illustrates a single pole, double-throw (SPDT) device. Descriptions from the patent text are as follows:

Fig. 1 – device shown in nonoperated position

Fig. 2 – device shown in operated position

Fig. 3 – cross-section

1 – glass envelope

2 – terminal

3 – resilient magnetic member

4 – non-magnetic member

5 – conducting member

6 – magnetic member

7 – insulating piece}

What Is a NO Type Reed Switch?

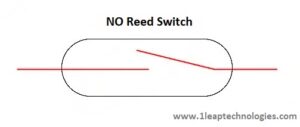

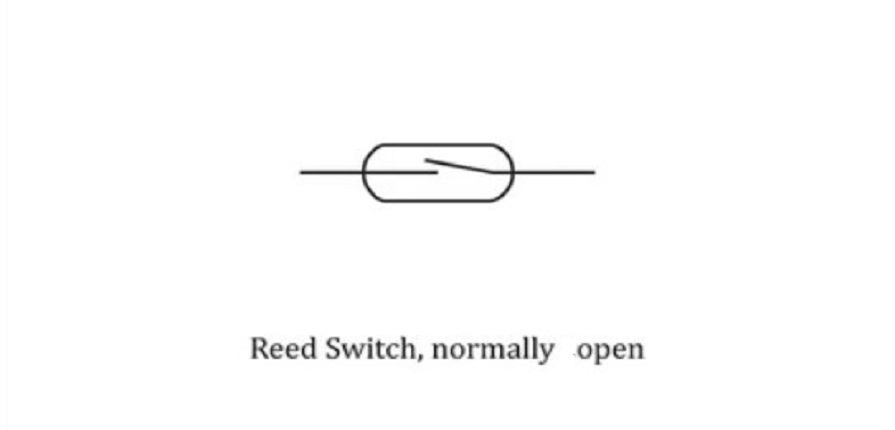

Reed Switch Symbol

At its core, a NO (Normally Open) type reed switch is a simple yet effective magnetic switch. Picture it as a vigilant gatekeeper: it remains open until a magnetic field nudges it closed. When activated, the switch completes an electrical circuit, allowing current to flow. This elegant simplicity is why reed switches have maintained their relevance since the early days of electronics.

How Does It Work?

Let’s break it down:

- Structure and Operation

The reed switch consists of two ferromagnetic reeds sealed within a glass envelope. In a NO configuration, these reeds stay apart under normal conditions. When you bring a magnet close, the magnetic field overcomes the gap, causing the reeds to attract each other and close the circuit. - Transition in States

Initially, the circuit is open—just like an uninvited guest at a closed door. However, the presence of a magnetic field acts like a friendly knock, prompting the reeds to connect and complete the electrical pathway. Once the magnet is removed, the reeds return to their open state, ready for the next cue. - Reliability in Action

This swift response ensures that the NO type reed switch performs reliably in a myriad of applications, from security systems to precision instruments.

Key Advantages of NO Type Reed Switches

Efficiency and Simplicity:

NO reed switches boast a minimal design, which translates into high reliability and low power consumption. They do their job without unnecessary complexity—a testament to the beauty of traditional engineering.

Fast Response Time:

You can count on these switches to react instantly. Once the magnetic field appears, the circuit closes without delay, making them perfect for applications where timing is everything.

Durability:

Encased in glass, the reeds are shielded from environmental contaminants. This design ensures long-term durability even in harsh conditions.

Cost-Effective:

In a world where high-tech sometimes means high price, NO type reed switches remind us that simplicity can be both effective and economical.

Applications Across Industries

Transitioning from theory to practice, let’s explore where these switches excel:

1. Security Systems

When a door or window moves, a magnet mounted on the frame interacts with the reed switch, triggering an alarm. It’s a simple yet effective mechanism that has protected homes for generations.

2. Consumer Electronics

From smartphones to laptops, reed switches can be found in devices that require precise sensor input. Their low power draw and reliability make them indispensable in today’s compact gadgets.

3. Automotive Industry

Automobiles rely on various sensors for safety and performance. NO reed switches help monitor everything from seatbelt buckles to fluid levels, ensuring that safety standards are met without compromise.

4. Medical Equipment

In medical devices, reliability is non-negotiable. NO reed switches provide consistent performance in critical monitoring systems, contributing to patient safety and accurate diagnostics.

Choosing the Right NO Reed Switch for Your Application

When selecting a reed switch, consider the following factors:

- Magnetic Sensitivity:

How strong is the magnetic field required to activate the switch? For delicate applications, choose one that responds to weaker fields. - Operating Environment:

Assess temperature, humidity, and potential exposure to chemicals. A switch with a robust design will perform better in challenging conditions. - Size and Form Factor:

Ensure that the physical dimensions fit your device. The compact nature of reed switches often makes them ideal for space-constrained applications. - Contact Life:

Evaluate the expected number of cycles. A switch that endures repeated use is vital for long-term reliability.

Installation and Maintenance Tips

Installing a NO type reed switch is as straightforward as it gets:

- Proper Alignment:

Align the magnet and the switch correctly to ensure optimal activation. A misaligned setup can lead to unreliable performance. - Secure Mounting:

Use appropriate fixtures to prevent movement. Even the smallest shifts can affect the switch’s operation. - Regular Testing:

Periodically test the switch to confirm that it reacts to the magnetic field as expected. This simple check can save you from unexpected failures. - Avoid Physical Stress:

Although robust, reed switches are not immune to excessive physical shock. Handle with care during installation and maintenance.

Troubleshooting Common Issues

Even the best devices occasionally need a bit of attention. Here are a few common issues and how to address them:

- Delayed Response:

Check for any obstructions between the magnet and the switch. Clean the area and realign if necessary. - Inconsistent Operation:

Inspect the switch for signs of damage or wear. If you notice any irregularities, replacing the switch might be the best course of action. - False Triggers:

Evaluate the surrounding magnetic fields. Other nearby magnets or electromagnetic interference can cause unintended activations. Shield the switch if needed.

Future Trends in Reed Switch Technology

Even as we lean on tried-and-true methods, the future of reed switches is bright. Engineers are exploring ways to integrate these switches into smart systems, merging the reliability of traditional designs with the sophistication of modern electronics. Innovations in material science may lead to even more durable and sensitive switches, ensuring that the NO type reed switch remains relevant for generations to come.

Conclusion: A Leap Toward Reliability

In a world that often chases the newest and shiniest, the NO type reed switch stands as a steadfast reminder that simple solutions can still conquer complex challenges. From its humble beginnings in telecommunications to its modern-day ubiquity, this classic component proves that tradition and innovation can dance together in perfect harmony.

If you’re looking for a practical, forward-thinking option, 1 LEAP NO type Magnetic switches provide a shining example. They combine the time-tested reliability of reed technology with a robust, modern design—offering a leap forward in efficiency, cost-effectiveness, and overall performance. In other words, they honor the past while forging a path into the future.

May your projects flourish under the watchful care of these unassuming yet mighty switches, bridging the gap between yesterday’s wisdom and tomorrow’s potential. Embrace the magnetic charm, harness the reliability, and let the legacy of NO type reed switches guide you to success—one leap at a time.

Discover the power of 1 LEAP today and take your innovations to new heights.

Recent Comments