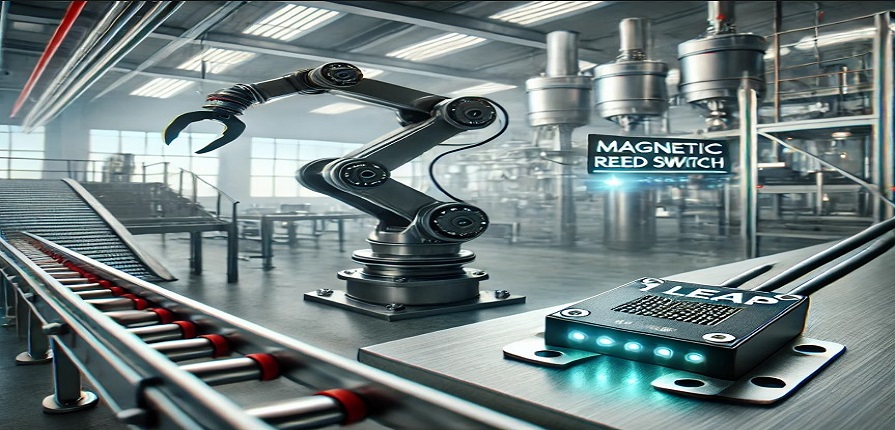

Magnetic Reed Switches: Usage and Benefits in Industrial Equipment

Magnetic reed switches are crucial components in modern industrial automation. These simple yet highly effective devices enhance safety, precision, and operational efficiency across various industries. Whether used in heavy machinery, conveyor systems, or fluid level monitoring, magnetic reed switches offer reliability and durability in harsh environments.

How Magnetic Reed Switches Work

Magnetic reed switches consist of two thin, ferromagnetic contacts enclosed in a sealed glass tube filled with an inert gas. When exposed to a magnetic field, the contacts attract and complete an electrical circuit. Once the magnet moves away, the contacts return to their original position, breaking the circuit. This contactless switching mechanism makes them highly efficient and long-lasting.

Common Industrial Applications of Magnetic Reed Switches

1. Position and Proximity Sensing

Magnetic reed switches detect the position of moving parts in industrial machinery. They help ensure safety by confirming that doors, gates, and panels are securely closed before operation begins. This is especially useful in automated assembly lines and robotics.

2. Fluid Level Monitoring

Industries that handle liquids, such as chemical processing and water treatment, rely on reed switches for level detection. These switches are integrated into float mechanisms to activate or deactivate pumps and valves based on liquid levels.

3. Security Systems

Many industrial security applications use magnetic reed switches for door and window monitoring. They trigger alarms if an unauthorized entry is detected, providing an extra layer of security in manufacturing plants and warehouses.

4. Conveyor Belt Automation

Conveyor systems use magnetic reed switches to track object movement and control motor operation. They help automate sorting and packaging processes, reducing manual intervention and improving efficiency.

5. Pneumatic and Hydraulic Systems

Reed switches play a crucial role in pneumatic and hydraulic cylinders by detecting piston position. This enables precise control of pressure and fluid movement, preventing system failures and enhancing performance.

Key Benefits of Magnetic Reed Switches in Industrial Use

1. High Reliability and Durability

Since they operate without physical contact, magnetic reed switches experience minimal wear and tear, ensuring longevity. They function effectively even in extreme temperatures and harsh environments.

2. Energy Efficiency

These switches require no continuous power supply to maintain their state, reducing energy consumption. This makes them an excellent choice for energy-conscious industries.

3. Compact and Lightweight

Their small size allows easy integration into industrial machinery without adding significant weight or requiring extensive modifications.

4. Cost-Effective Solution

Compared to other sensing technologies, magnetic reed switches offer a low-cost yet highly efficient solution for automation and monitoring needs.

5. Versatility Across Industries

Magnetic reed switches are adaptable to various industrial applications, including aerospace, medical devices, automotive, and smart manufacturing systems.

Why Choose 1 LEAP Magnetic Reed Switches?

For industries looking for a reliable magnetic reed switch, 1 LEAP Magnetic Reed Switches stand out. These switches are designed for precision, durability, and seamless integration into industrial applications. With their high-quality construction and superior performance, they ensure operational efficiency and safety.

Final Thoughts

Magnetic reed switches continue to play a vital role in industrial automation. Their ability to provide accurate sensing, durability, and energy efficiency makes them indispensable across various industries. Whether for safety, automation, or monitoring, investing in high-quality magnetic reed switches like those from 1 LEAP can enhance productivity and reliability in industrial equipment.

For more details on 1 LEAP Magnetic Reed Switches, visit 1 LEAP Technologies.

Recent Comments